42 thermal transfer labels definition

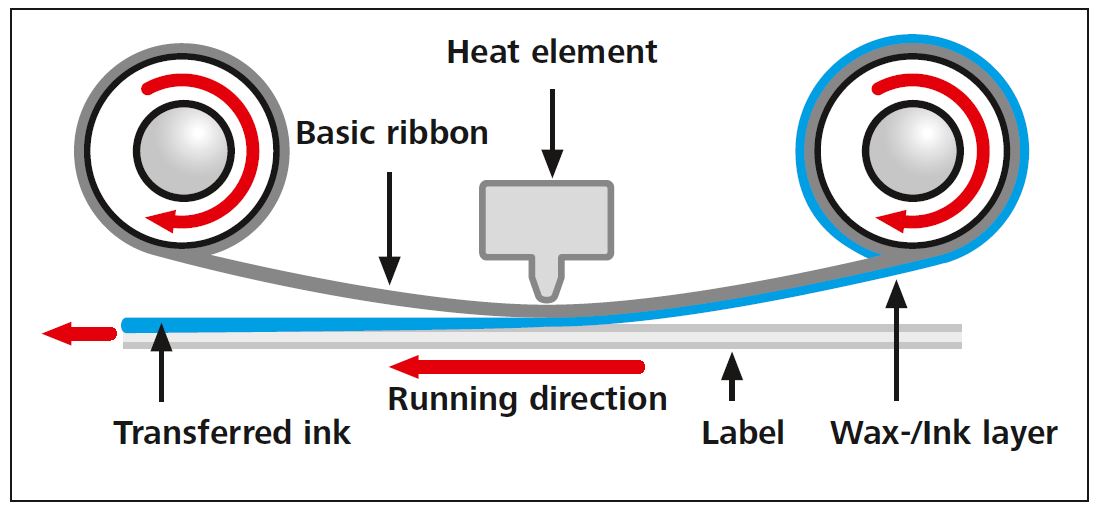

Thermal Transfer Printing | Hub Labels A durable label solution for harsh environments. Thermal transfer printing is printing that is performed by what is called a ribbon roll. The ribbon roll is heated up by the printhead which then melts it on to the label to form the desired text or image. A label that was created through a thermal transfer process will typically have a glossy ... Thermal Transfer Labels | Barcodefactory Low Prices Thermal Transfer Labels. Thermal Transfer technology uses a ribbon to transfer an image onto the label material types such as paper and synthetic. These labels are perfect for indoor or outdoor use and support a medium to long-term lifespan. Thermal Transfer Labels require a ribbon. Popular Label Sizes

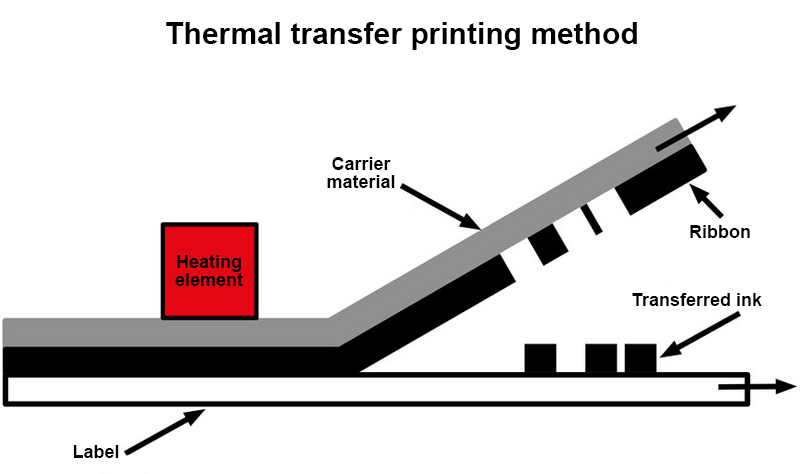

Definitive Thermal Transfer Ribbons - ThermalTransferLabels.com When heated by the thermal head of a thermal transfer printer, they transfer the ink layer to a label that can then be applied to goods, packages, equipment, and more. Thermal transfer ribbons are used to print labels, barcodes, and other variable and non-variable information. Learn more about the uses and benefits of thermal transfer ribbons.

Thermal transfer labels definition

Thermal-transfer printing - Wikipedia Thermal transfer is a popular print process particularly used for the printing of identification labels. It is the most widely used printing process in the world for the printing of high-quality barcodes. Printers like label makers can laminate the print for added durability. Thermal transfer printing was invented by SATO corporation. What does "Thermal Transfer" mean on Product Labels? Conversely, "Thermal Transfer" printers use special ribbons with colored ink that gets melted by the printhead in the chosen areas and the ink "transferred" to the material being printed on (hence the name). This technology is often used by customers wishing to "overprint" product labels with variable data (such as expiry dates, lot numbers etc). Home - ThermalTransferLabels.com Zebra ZD. Thermal Transfer Printer Review - Zebra ZD An upgrade to Zebra's popular GX and GK series, the ZD thermal transfer printers series offers a broad range of features, all of them packed into a compact…. Read More ». September 12, 2022.

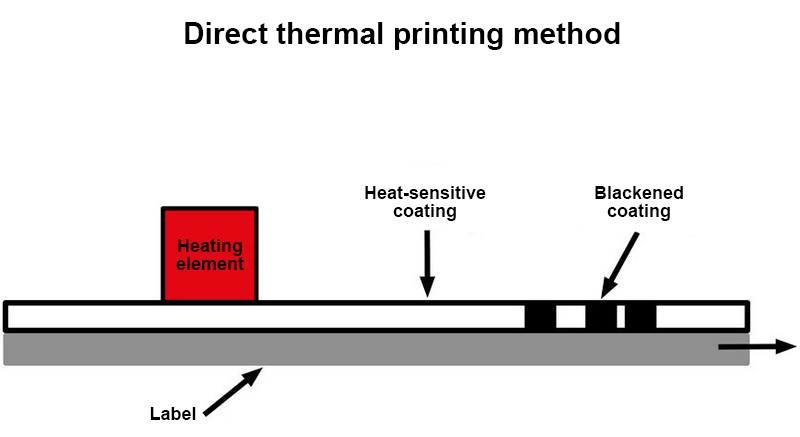

Thermal transfer labels definition. What are Thermal Labels? | Zebra What Are Thermal Labels? Thermal labels use heat to create an image. Thermal transfer uses a thermal ribbon where heat from the printhead releases the ribbon attaching it to the label surface. Direct thermal images are created when heat from the printhead causes components on the label surface to mix causing them to (usually) turn black. Thermal Transfer vs Direct Thermal Printing: Which is Best? When a thermal transfer label or tag passes through a thermal transfer barcode printer, heat from the print head melts the wax or resin. This process transfers ink to the label. The result is crisp, high-definition images of the highest quality—which is why thermal transfer printing is perfect for applications that require durable, long ... Considerations for Thermal Transfer Labels - Mammoth Labels & Packaging To start, thermal transfer labels have excellent print definition for text, images and barcodes. These types of printers can produce stable and durable images that are long-lasting and resistant to fading. What is a thermal printer? - Label Printers Thermal printers are now very common for commercial enterprises and in industrial workplaces. Movie tickets are often printed using this process as well as labels in grocery stores and even lottery tickets. Essentially, a thermal printer uses heat to copy an image onto a material and inkjet printing uses ink to copy the image onto material.

Thermal Transfer - Continental Datalabel The thermal transfer printing process involves the use of a ribbon along with rolled or fan-folded labels. Like direct thermal, heat plays a part in thermal transfer printing; however, the heat does not come into contact with the media. Instead, the hot printhead melts ink in the ribbon to create a sharp, crisp image on the label's surface. Understanding Thermal Labels: Direct Thermal vs. Thermal Transfer Thermal labels are the perfect solution for printing information on demand such as barcodes, ingredients and dates. There are two methods to consider, each with their own advantages; direct thermal and thermal transfer. Choosing the right thermal option requires matching application requirements with the capabilities of your printer. Thermal Transfer Printing Problems and Solutions Reverse transfer; Reduce printhead temperature ("heat factor"), one level at a time; Increase print rates, one level at a time; Excessive Noise During Printing. Sticking between ribbon and "bleeding" label adhesives or label coatings; Reduce printhead temperature ("heat factor"), one level at a time; Increase print and/or slew rates, one level ... Direct Thermal vs Thermal Transfer Labels | Diversified Labeling Solutions What Are Thermal Transfer Labels? Thermal transfer labels use ribbons that hold ink to "transfer" the image onto the media. This is done with the same printheads used in direct thermal printing. A lot of the roll media printers are set up to print both T.T. and D.T. The determining factor is whether there is room or a place to hold the ribbon roll.

Thermal Transfer Printing Problems & Solutions | United Ad Label Bar expansion is typically a print speed problem. Try reducing the speed one setting and then test a few labels to determine if that step resolves the problem. If not, adjust the setting one more level and try again. Another possible cause is the ribbon media. An old or inferior ribbon can cause bar expansion as well. Try changing the ribbon. Direct Thermal Label vs. Thermal Transfer Label Difference (Infographic ... Thermal transfer labels are used for the thermal transfer printer. The print head applies heat to the ribbon, which melts either wax or a special resin onto the label media, bonding to it. You will be able to see the ink is removed from the ribbon to be bonded with the label to create your image. Quick Tips: Thermal Transfer Labels - Piedmont National Corporation THE TOTAL THERMAL TRANSFER SOLUTION: Ribbons - Diversified offers a complete line of thermal transfer ribbons to meet all of your client's needs; from wax, wax resin and resin coatings. Wax, Wax/Resin and Resin Coatings. High Density Formulations to Provide Consistent Scan Rates. Excellent Edge Definition and Print Quality at High Speeds. Thermal Transfer Labels- Lowest Price in the Industry Our products are perfect for industrial and desktop thermal printers and are compatible with all major printer brands, including Zebra, Intermec, Sato, and Datamax. Thermal transfer labels use a heat-sensitive carbon ribbon that is melted on onto the label. Unlike direct thermal labels, thermal transfer labels always require a thermal ribbon ...

Direct Thermal V.S. Thermal Transfer - Abbott Label Thermal Transfer. Ideal for high volume use applications. Utilizes thermal transfer ribbon. Color printing—great for logo and product branding labels. Print accuracy, precise edge definition—great for barcode printing. Resistant to fading and smearing. Durable & Versatile. Can print on a variety of label materials.

What is Thermal Transfer Printing? | Technicode, Inc. Thermal transfer printing involves melting resin-based ink or wax ribbons onto printing media, which results in a high-quality, long-lasting image. Manufacturers primarily use thermal transfer printing to print labels due to its resistance to moisture and heat that allows for optimal durability.

Définition of thermal transfer printing | inkanto by ARMOR-IIMAK Thermal transfer is a fast printing process that allows the printing of variable data, controlled directly via dedicated software. This software connected to the printer transmits the data and printing information that will make each product unique. Widely used for label printing, Thermal Transfer technology is compatible with countless ...

Thermal Transfer Labels | Labels Direct, Inc. A label produced with the thermal transfer method will not blacken when a fingernail or other hard object is drawn across it. Thermal transfer labels are used for permanent solutions such as product identification, asset tags, tickets, and certification labels. Their durability also makes them appropriate for cold storage and outdoor applications.

Direct Thermal and Thermal Transfer Printing | Zebra Thermal Transfer Printing Thermal transfer printed labels are easily identified by the crisp, often glossy, printed surface. The clarity is achieved by using a thin ribbon roll that when heated by the printhead melts onto the label to form the image. The ink is absorbed so that the image becomes part of the media.

Home - ThermalTransferLabels.com Zebra ZD. Thermal Transfer Printer Review - Zebra ZD An upgrade to Zebra's popular GX and GK series, the ZD thermal transfer printers series offers a broad range of features, all of them packed into a compact…. Read More ». September 12, 2022.

What does "Thermal Transfer" mean on Product Labels? Conversely, "Thermal Transfer" printers use special ribbons with colored ink that gets melted by the printhead in the chosen areas and the ink "transferred" to the material being printed on (hence the name). This technology is often used by customers wishing to "overprint" product labels with variable data (such as expiry dates, lot numbers etc).

Thermal-transfer printing - Wikipedia Thermal transfer is a popular print process particularly used for the printing of identification labels. It is the most widely used printing process in the world for the printing of high-quality barcodes. Printers like label makers can laminate the print for added durability. Thermal transfer printing was invented by SATO corporation.

Post a Comment for "42 thermal transfer labels definition"